Project Updates

We organized an informational tour with our community’s partner friend who’s an engineer. He has been part of Aquaponics for the last 10 years, and he will tour our team and the tech museum aquaponics team into some Aquaponics farms. We think this is a great idea because we will get more ideas on how to start, what parts can we innovate, and get to know more the nature of the aquaponics.

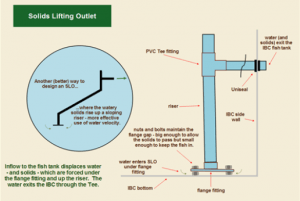

As in for the connection between the Aquaponics and the HOMEBIOGAS, a solid lifting overflows method (SLO) will be employed to separate the fish waste from the water that goes to the plant’s grow bed as shown under figure (#). They maintain a constant level in the fish tank while pulling all the solids off the bottom of a tank to an outside source. Outside the storage tank, a pump will make the sludge and some water to flow over 4” PVC pipes to the HOMEBIOGAS. Outside the storage tank, a weight sensor will be placed, and it will be used as reference for the microcontroller. For the microcontroller, the team will use an Arduino Uno. Every time the weight sensor weighs an extra weight, it will command the pump to extract the fish waste and plant residues and deliver it to the Biogas unit.

Brainstorming Ideas

- Focusing how to sense the waste in the water?

- Weight sensor idea

- Laser beam idea (light intensity): Photoresistors

- Water quality sensors?

- Rate of how much waste goes into the tank; also, the rate at which methane is produced

- How to extract the waste?

- Biofilters

- Pool pump?

- Check out pump that is already at farm pumping water from fish pond to aquaponic beds

Articles/Research

The concepts of both biogas and aquaponics are new to our team, so much background research has been needed in order to familiarize ourselves with what we are delving into. There are many biogas systems out on the market, some using solely food scraps, some using solely animal feces, and some using a combination of the two. The biogas unit that is in place at the community garden is the latter of that list. It combines both animal waste, in the form of manure (or in our case fish waste), and food scraps. This is called co-digestion biogas production, which is a more efficient way to produce methane. The article below tested three different biogas systems and found that the combination of food and manure resulted in the most methane production.

Co-digestion Biogas Production

- Energy rich waste (fats, oils, food scraps) added to wastewater digester (fish excrement)

- More methane production via co-digestion than food waste alone

- Paper shows values of methane for systems using: food waste, manure, or combination

Zamanzadeh, M., Hagen, L. H., Svensson, K., Linjordet, R., & Horn, S. J. (2017). Biogas production from food waste via co-digestion and digestion- effects on performance and microbial ecology. Scientific Reports, 7(1), 1–12. https://doi.org/10.1038/s41598-017-15784-w

Pictures

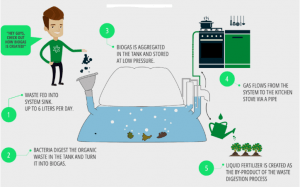

The biogas unit installed at the community garden is produced by Homebiogas. Fish waste, and food scraps are put into the lower chamber of the unit, bacteria from the waste material goes to work digesting the rest of the food scraps and waste material and the biogas (methane) is produced and collected in the upper chamber of the system. This can then be fed to a stove where the methane will be used to cook food. A by-product of the system us a liquid fertilizer that can be used throughout the garden. An illustration of how the system works is shown below.