Initially, combining the two distinct needs of the Gilroy Compassion Center and AtHack Inc was a glaring setback for the team. We have found a solution by working on two separate but related deliverables for each community partner: new working lockers for the GCC and a more complex smart locker system design for AtHack. Acknowledging the lack of tech support the GCC has had with their smart lockers, we are planning on creating easy to use mechanical lockers with charging ports inside. The lockers are set to be modular in design so there will be a level of customizability with the size and shape of locker doors. The GCC locker designs will serve as a starting point and will be updated with more features for the AtHack design.

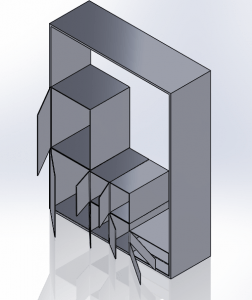

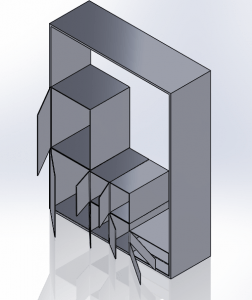

Currently, two locker designs have been drafted in SOLIDWORKS incorporating the Ikea inspired idea, one shown below.

We are also considering the concept of an openable frame that opens all lockers at once to act as a master key for all the lockers. The lock design and manufacturing company, Digilock, also provide a possible solution to a smart mechanical lock. The product we are considering offers a fair amount of security with its mechanical user set combination and master key override.

Digilock’s mechanical locker lock

Find more information here: https://digilock.com/locker-locks/mech/

On, Friday, October 12, we met with technical advisor Dr. Rhee to discuss the potential problems with the designs. She has given us valuable insight on subjects to analyze with the proposed locker such as the heat generated from the outlets if all were used at once and a manufacturer-friendly design.