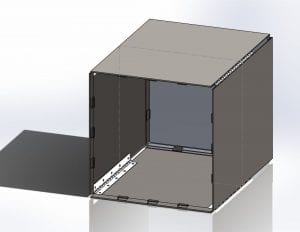

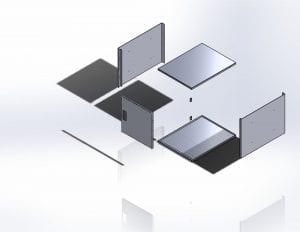

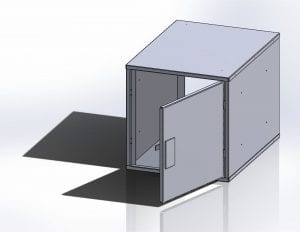

Testing continues with the locker system. Expected power usage is being measured for expected and worst case. Heat testing and tipping over testing is currently waiting for the production model to continue.

The Gilroy Compassion Center has validated and verified the functionality and design of the prototype locker. They have provided feedback that has allowed the team to move forward with the production model.

The software side of the project has begun to work on the user mobile interface that will be used for the lockers. The back end software development has been completed but it will not be tested until the interface design has been completed. The interface will be created using Adobe XD and will follow a similar structure to that of Amazon Lockers. Following the current flow chart created by the team from Fall 2018 shown below, the design will include a similar structure with a better unique look that will make the SmartMake mobile site more engaging.

Lastly, the team is also planning on incorporating a solenoid lock with WiFi capabilities. Said design will allow us to connect the locks to a mobile device. Since the software side is still in the design/ prototype creation phase, this task needs to be completed in order to move forward with the remaining production specs. More information and updates will be available in the upcoming weeks.