Team: Aquaponics/Biogas

Project Updates

As mentioned in the previous post we are going to be focusing our entire senior project at Middlebrook Garden. But first….

WE HAVE INOCULATED THE BIOGAS UNIT!! One of our team members, Aaron, took charge of inoculating the biogas unit at Middlebrook Garden. This was a messy process that involved picking up close to 100 pounds of horse manure, driving 70 miles, and then getting his hands (and clothes) dirty in the process of putting the manure into the biogas unit. Thanks again Aaron!

Now for the rest of the updates….

While brainstorming ways to combine the current aquaponic and biogas systems at the garden we have come to the conclusion that we will need to replace the current overflow tank from the fish pond. Currently, the level of the overflow tank is too low to utilize gravity to flush the fish waste from the barrel into the biogas unit. Aside from the height issue, the drain on the barrel is too high from the bottom of the tank. So, given these issues we have decided that a new tank would be necessary.

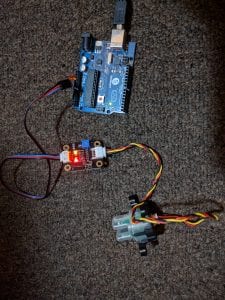

After much debate and testing we have also decided upon the type of sensor we will use to determine the level of fish waste in the overflow tank. This was originally designed to use a weight sensor, but we found that the difference in density between the fish waste and water is less than 1%. With such a small discrepancy in weight there is too much room for error with this method. We found that a turbidity sens or will work much better for our situation. A turbidity sensor measures the amount of light transmitted through the given medium, in our case this is water. When the water is dirty, (from the fish waste) less light will be transmitted through the sensor, which corresponds to a low number, while clear water will corresponds to a high number. The sensor will be attached to a microcontroller (Arduino) and the digital print out will be the turbidity level. A picture of the connection between the Arduino and the turbidity sensor can be seen to the right.

or will work much better for our situation. A turbidity sensor measures the amount of light transmitted through the given medium, in our case this is water. When the water is dirty, (from the fish waste) less light will be transmitted through the sensor, which corresponds to a low number, while clear water will corresponds to a high number. The sensor will be attached to a microcontroller (Arduino) and the digital print out will be the turbidity level. A picture of the connection between the Arduino and the turbidity sensor can be seen to the right.

We have also began construction of the replacement overflow barrel. We first thought a conical tank would be the best type of tank for our setup, but due to the incredibly high cost and marginal benefit, we decided that a translucent 55 gallon drum would work as well. We purchased a used 55 gallon barrel for only $25, what a deal!

The next step was cutting off the top so we will have easy access to the inside to place a swirl filter and the turbidity sensors at the bottom. Then to make a seal with the lid, that can be removed when necessary, we placed rubber housing(old garden hose) around the rim of the barrel. This will allow us to get a tight seal when the lid is tightened down with buckles/latches. This has still not been decided upon but that is one of the next steps. Below are pictures of the inside of the barrel and the rubber housing.

Our next goal is to place a drain on the bottom of the barrel and connect it to an actuated valve that will connect to the Arduino. The readings from the turbidity sensor will determine when the valve will open and close.

It was nice to finally get our hands dirty and start the construction of the project. We are excited to see our project taking off!