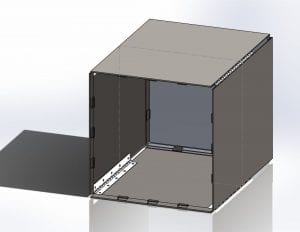

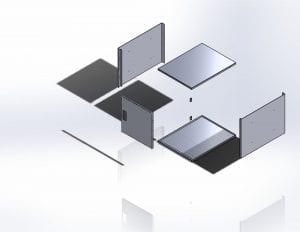

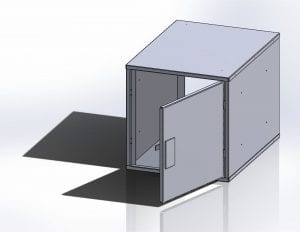

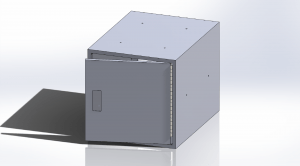

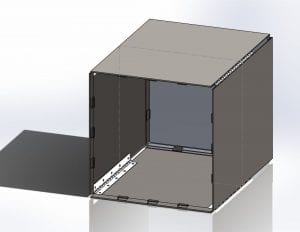

The SmartLockers team discussed ideas for the concept folding locker. The goal of the locker is to have a set of folding locker to accommodate for pop-up camps and field events. The design will allow for quick deployment and take-down. The idea was a brain child of our community partner Ehb Teng from AtHack, inc. A few CAD drawing were made to further develop the design.

Regarding the main design. There are a few tasks that need to be completed. The first task is to test the prototype’s heat dissipation, tilt safety and current draw to ensure design verification of the locker. The team is scheduled to test the prototype next week before meeting with GCC to validate the design. The second task is to get feedback from the Gilroy Compassion Center to validate and verify the functionality and design of the prototype locker. A meeting has been scheduled to meet with the GCC. The third task is to integrate the user interface software with the locker and test its usability. Once these tasks are approved and verified, our last task would be to send the design to a outside machine shop to build a set with the specified materials and dimensions. A Prototype was made using a thinner gauge sheet metal to get an idea of the dimensions.

Additionally, the team presented at the IEEE Expo in February. The expo was in partnership with San Jose State University and Santa Clara University to show of community projects from both schools. A handful of participants received grants funding to expand the scope of the projects. The project that received funding for SJSU EPICS include, Team Aquaponics, Underwater ROV team, and the SmartLocker Team.