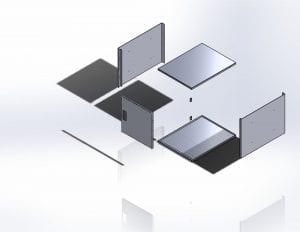

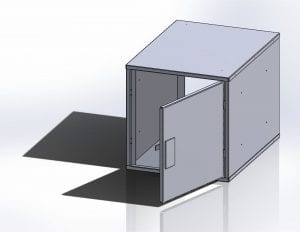

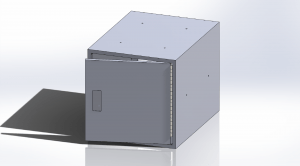

This week, the SmartLockers team developed sketches for some new concepts and ideas to integrate into our existing design for the purpose of making the lockers more modular. The team met this week on February 12 to discuss these lockers’ new design; the sketches and brainstorming are shown on the image to the right.

The idea is to add hinges on the inside edges of each locker to make them easier to set up and put away. In other words, this would be a “fold-able” concept. This idea surfaced when it came to stability. One team member pointed out that by placing rod-type of design on each edge, the lockers would be placed in one space and would not be able to move once set up. Additionally, a wooden locker prototype was also shown and discussed upon among the team. Lastly, this week the team also focused on designing a poster and presentation for the IEEE expo on February 18.

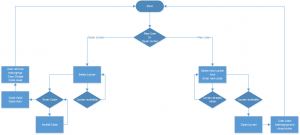

After creating a draft for both items, it was then presented to Dr. Julia Thompson during the following class hours. Using Dr. Thompson’s constructive criticism and feedback, the team worked on polishing the project presentation while spending time during class to finish the project poster. This included editing text, creating new image concepts, and striving to make the poster look more appealing. After working on it later that night, the team sent the poster to Dr. Thompson to be printed. To the right is the final poster creation that will be shown and demoed at the expo.