Blog #2

Team: “Veggie Sticks”

Project Updates

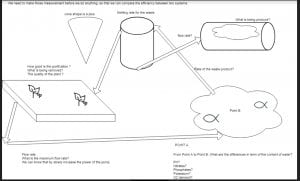

The IEEE Conference is upon us! We went through several drafts of our poster and have come away with a nicely polished and elegant product(shown below). The goal of our poster was to showcase and pitch our idea of the “stand-alone” unit that we originally had planned on creating. Due to changes made to the project, we are not actually going to construct this “stand-alone” unit, however, we hope to pitch this idea to some companies at the conference. A second thought of ours is to inspire future EPICS teams to work on the replicable unit. The rest of the poster provides an overview to what systems we will be incorporating at Middlebrook Garden, with very brief descriptions of each. We then show the design of what we will be installing at the garden.

The poster itself has minimal wording, and includes graphics that will hopefully spur questions from the viewers. The goal was to create a poster that looked exciting, and provided just enough information so the viewer had somewhat of an understanding of the project, yet, they would need to ask questions in order to find out more.

Aside from the poster presentation we have created an awesome semester plan as mentioned last time, and our awesome advisor Dr. Han has approved it!

Next Steps:

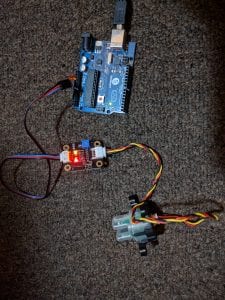

Our team has a few tasks that will begin this coming week. Lok and George are in charge of the electronic portion of the system. They are creating a board that will be a much cleaner setup of the sensors and digital display. Aaron, Chris, and Hector are dealing with the construction of a stand for the waste tank and will begin testing the barrel for leaks. They will also determine the flow rate through the automated valve which will be used as a fail safe if our turbidity sensors are not accurate enough to control when the valve closes.

We are currently waiting for a response from our community partner, so the installation will be on hold. This is fine for now, since we need to construct the stand and do some testing on the barrel before we install it. On top of this we can also begin to brainstorm ideas on how to incorporate an educational display into the project.