The team found the design review incredibly helpful and have decided to implement a feedback loop for better accuracy and repeatability. To do this, the project will utilize a closed loop linear encoder on the slide bar which will measure the position of the end mill and avoid thermal expansion deviations of the lead screw that tend to cause problems with accuracy when a rotary encoder is used. In addition, the team plans to turn more focus on safety concerns. The plan is to reach out to small startups in San Jose with similar projects in hopes of discussing their learning curves along the way to implementation and gain the knowledge necessary to avoid safety issues as much as possible with end use of the CNC. The team is grateful for the advice and hope to improve on the project with the insight gained from community partners.

Category Archives: Home

Status. Updates. Information.

CNC Machine Prototype

Parts for the CNC Machine Prototype

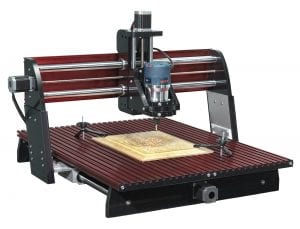

The project aims to create this CNC by building a prototype early on in the design process. By constructing a prototype, the team hopes to gain a better understanding of how the machine works, both in mechanism design and software design. After the prototype is made, the team will modify the design to accommodate a laser cutter and safely scale the product to the desired specifications.

Currently, the parts for the prototype of the CNC machine have been ordered and received. Using the prototype, the parts were measured and added to the bill of materials for preparation to create the CAD (Computer-aided design) of the parts for the final product. The prototype of the CNC machine will be assembled and programmed to test the design and functionalities of the CNC machine.

Community Partners

http://www.sjsu.edu/epics/makerspace/

http://www.sjsu.edu/epics/makerspace/

The Charles W. Davidson College of Engineering is an institution at San Jose State University that has educated tens of thousands of engineers who have gone on to work in Silicon Valley and all over the world. They facilitate learning by providing student support in the form of promoting clubs and organizations as well as offering a few spaces to students where they can develop ideas and learn how to implement their conceptual designs. The Makerspace provides students precisely this and helps them to bring their projects to life while gaining hands-on experience with the design process. The workroom is equipped with tools such as soldering, welding, and water-jet stations and is open for the engineering students to use.

Plans for the Makerspace

2-in-1 Computer Numerical Control Machine

Currently, The Makerspace does not have a functioning Computer Numerical Control (CNC) Machine, nor does it have a laser cutting machine for aspiring engineers to use on their projects. Purchasing a commercial CNC machine and laser cutter separately can cost well over one hundred thousand dollars. Not only are they expensive, they also take up a lot of valuable space within the workroom. These machines are not very user friendly and are difficult to use effectively without prior knowledge or training.

By creating a user friendly 2-in-1 machine, similar to the one shown above, this project aims to allow engineering students an effective way to prototype their projects. The CNC machine will be a dual function mill and laser cutter and students will be able to switch between cutting tools as needed. This versatile design will provide access to two separate manufacturing methods, but on a much smaller footprint than two separate machines, maximizing valuable floor space in the room. The time spent manufacturing on student projects will be reduced with the availability of this machinery. Costs for this project will be reduced by purchasing the required parts and assembling the machine on site.

About the team

Phat Nguyen – Project Manager for Fall 2018.

Phat is a Senior Mechanical Engineering student at San Jose State University.

Syeda Amena Ali – Manufacturing Engineering Lead for Fall 2018

Amena is a Mechanical Engineering Senior who is joining the EPICS program on the CNC machine project for her culminating year. She is happy to be working on a project that will hopefully outlive her time here at SJSU and also has a busy year ahead as Spartan Hyperloop’s Lead Simulations Engineer.

Weston Everett – Mechanical Design Engineer for Fall 2018

Simon Lee – Computer Engineering for Fall 2018

Simon is a Computer Engineering major currently working on the CNC machine project for EPICS. His areas of interest for his career revolves around software engineering and web development. On his free time, he enjoys traveling, going on adventures, hiking and bike riding. He joined EPICS because he wanted to work on a project to help him learn as well as benefit the community. His future plans will be to push his interest in software engineering and web development further and continue to learn new technologies.